BIESSE AKRON 845

Product Specifications

CONTROL SYSTEM

• Adjustable hanging command board to control the machine

• Incorporated electrical cabinet

TECHNICAL FEATURES

• Panel working height with straight edge (min/max): 10 – 60 mm

• Edge thickness in coils (min – max): 0.4 – 3 mm

• Track feeding speed: 14 m/min in rounding – 20 m/min in fine trimming

PANEL INTRODUCTION AND FEEDING SYSTEM

• Slide driving chain

• Top pressure unit made with double row of idle wheels

• Top pressure with electronic positioning controlled by NC

• Incoming panel separator with capacitive sensor

• Lateral panel support with aluminum track complete with supporting wheels

SQUARING UNITS

• In-feed pre-milling unit FI-701 with AUTO-SET for automatic centering of the tool relative to the panel. It is composed by nr. 2 motors with automatic timer intervention to avoid splinters on the panel. It is composed by nr. 2 motors with automatic timer intervention to avoid splinters on the panel

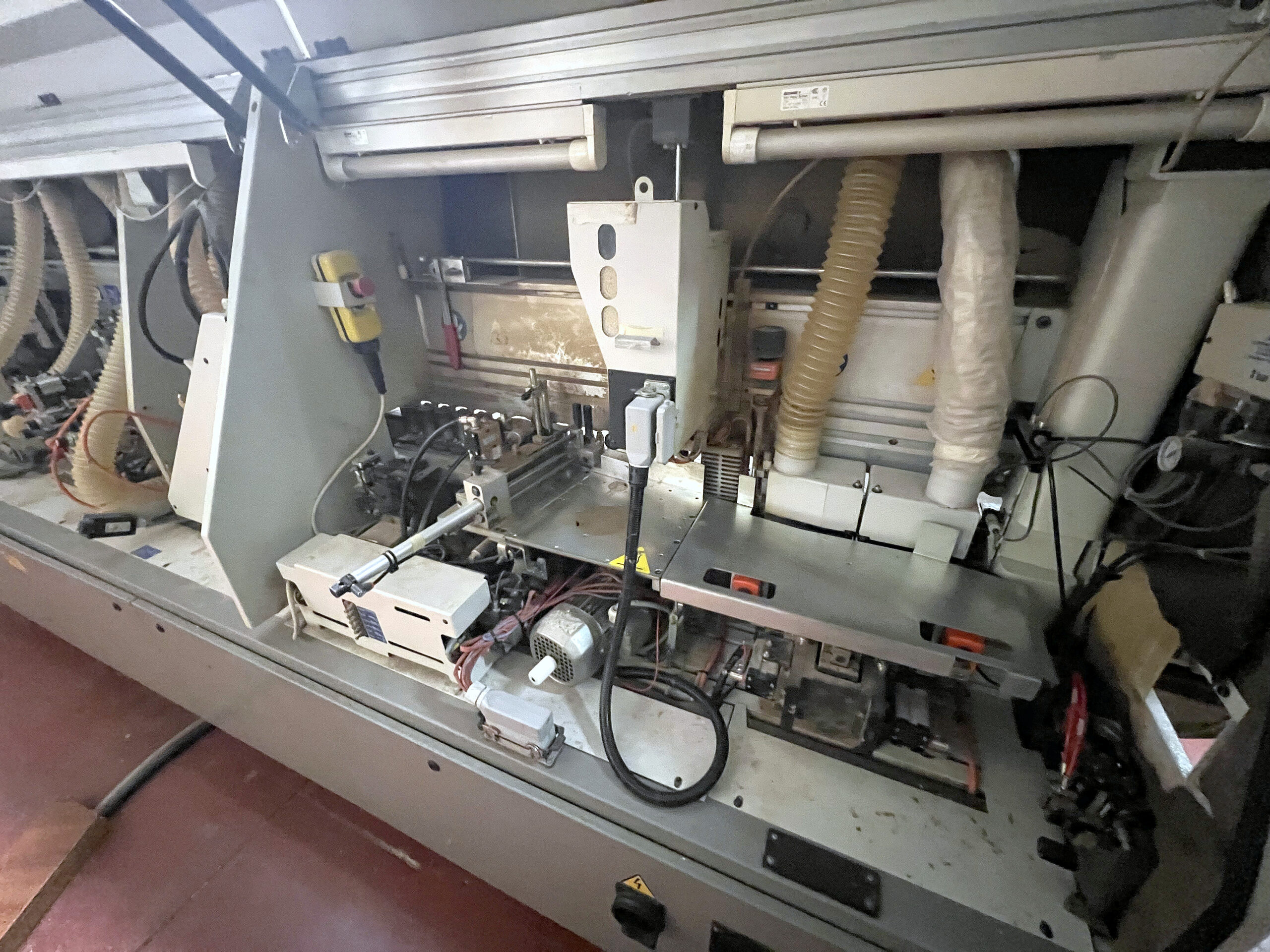

GLUING UNIT, LOADING AND EDGE PRESSURE

• Anti-adhesive unit ADZ-700 to allow the optimum cleaning of the workpiece on the upper and lower surface of the panel

• Infrared lamp IRL-700

• Gluing unit VC-710 with TEKNO GLUE system For optimal gluing in all working conditions

• Disk coil holder

• Glue tank for EVA glue – glue tank for hot melt glue

• Pre-melting system QM-703 for hot melt glue

• Guillotine to cut the edge in rolls with automatic regulation of the shear pressure

• Edge pressure roller with timed rollers on straight profile – Nr. 1 + 2 pressure rollers with positioning controlled by CNC with revolver with nr. 4 positions

EDGEBANDING UNIT

• End trimming unit IN-801 to cut the excess edge on the front and rear of the panel. Pneumatic tilting nr. 4 positions with pre-selection from control panel of cutting angle. FLEX system for edge trimming with controlled overhang: which allows the cutting position of the blades to be adjusted from the control panel to achieve a predefined edge overhang.

• Fine trimming unit RI-701 with NC positioning for trimming and chamfering of the excess edge on top and bottom of the panel – The unit is tiltable from 0°to 25° – FAST-RI system with nr. 2 working positions

• Rounding unit with nr. 2 motors CR-202 for automatic edge corners rounding on top and bottom of the panel – Complete with with nr. 2 positions Fast system preselectable by numerical control

• Edge scraping unit RBK 502 to eliminate imperfections resulting from previous machining on the top and bottom of the edge – Complete of chip collection box

• Glue scraping unit RC700 for the removal of excess glue from the join between edge and panel

• Overlaid Brushing unit SP-700 with nr. 2 motors for cleaning and polishing the rounded edge

NORM AND OPTIONAL FOR SECURITY

• Copy of original EC Declaration of Conformity

• Protection and sound-proof cabin of the working units

• Suction system on the top of the protection cabin